Calibration Services

Calibration is the documented comparison of the measurement device to be calibrated against a traceable reference standard. The reference standard is more accurate than the device/ artifact to be calibrated.

Calibration Services

Why Calibration?

In industrial process conditions, there are various reason for calibration.

Examples of the most common reasons are;

- Accuracy of all measurements deteriorates over time.

- Regulatory compliance stipulates regular calibration.

- Quality System requires calibration.

- Quality of the products produced.

- Safety – of customers and employees.

- Environmental reasons.

- Various other reasons.

Metrological Traceability

The reference standard that is used in calibration must also be calibrated maintaining metrologically traceability. This traceability means that the reference standard must have also been calibrated using a standard having much smaller measurement uncertainty. This calibration is normally performed by the National Metrology Institute (NMI). The traceability must ensure an unbroken chain of calibrations to national or international standard. If the traceability chain is broken at any point, any measurement below that cannot be considered reliable.

Metrological traceability means traceability to SI units through an unbroken chain of comparisons and continuous uncertainty additions at all levels starting from customers end going all the way to national metrological institutes and finally to SI units.

We offer calibration services

We offer In-house and Onsite calibration in following parameters.

Mass Metrology (In-house calibration).

Volume Metrology (In-house + Onsite calibration).

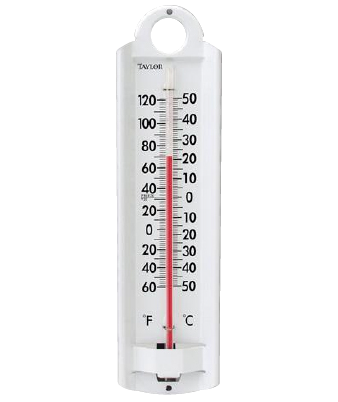

Thermal Metrology (In-house + Onsite calibration).

Pressure Metrology (In-house).

We assist organizations in developing their calibration program of all their equipment and take the responsibility for ensuring calibration of their equipment according to the program.

We perform metrologically traceable temperature-related mapping of facilities in order to document the validation of temperature distribution. This mapping is done in compliance with the requirements of regulatory authorities covering Good Manufacturing Practices (GMP).

We offer maintenance of equipment

Our qualified engineers help organizations to repair and calibrate their out of order equipment.